LEARN ABOUT WATERJETS

LEARN ABOUT WATERJETS

WHAT INDUSTRIES USE WATERJET CUTTERS?

From jewelry making to aerospace, waterjets are involved in the production of many products you may not expect. Due to the versatility of cutting with abrasive and the ease-of-use of OMAX's software, OMAX brand waterjets are in a wide variety of industries. Below are just a few examples of industries where OMAX abrasive waterjets are thriving.

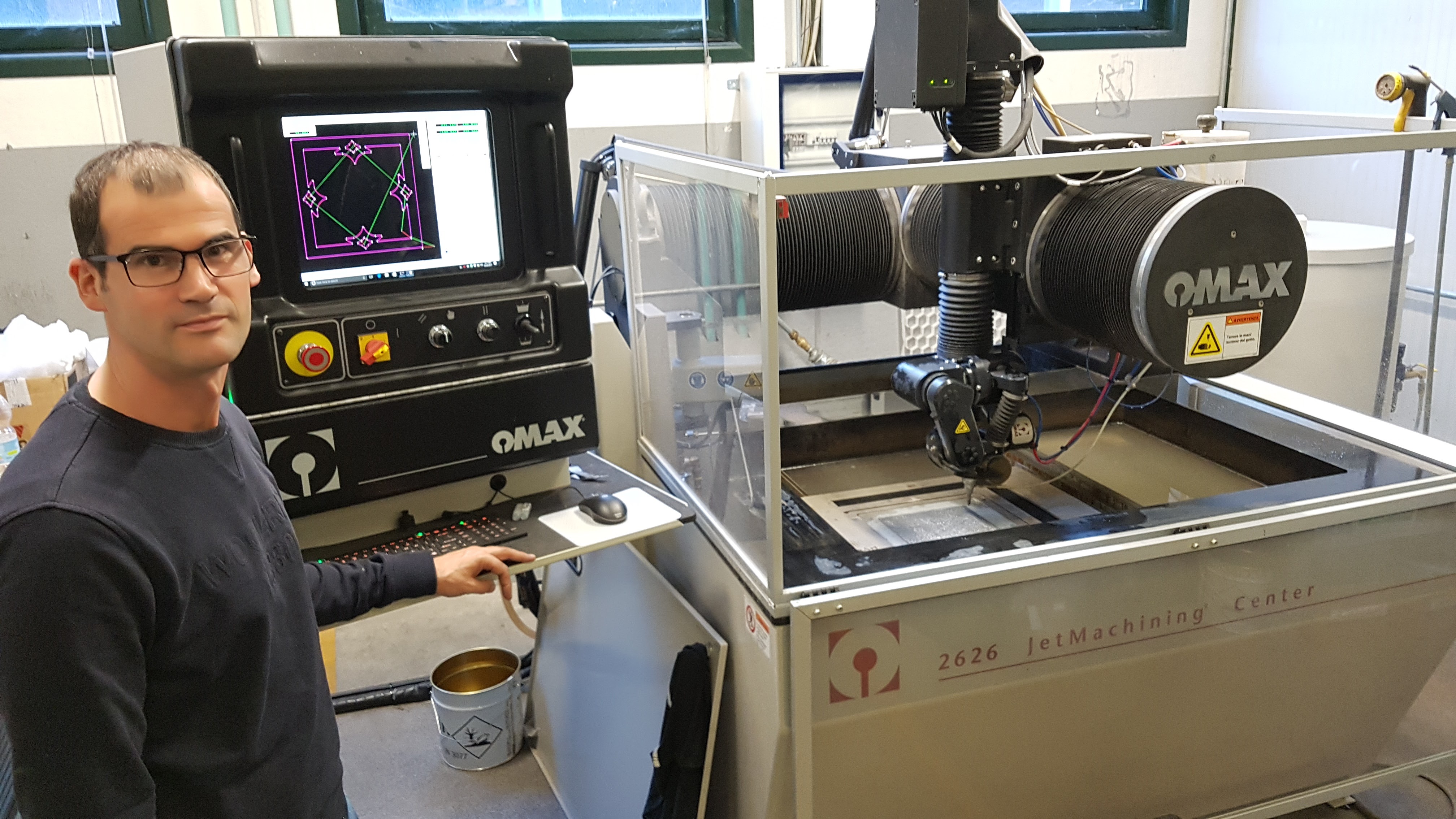

JOB SHOPS

Our easy-to-use abrasive waterjets add to your shop's capabilities to cut or machine a variety of materials at the speed and precision demanded by a range of industries.

STONE & TILE

Unparalleled precision and efficiency for cutting stone, tile, and marble, making them the ideal choice for your projects. OMAX waterjets are reliability and ability to cut different densities of materials easily make them versatile and dependable. With advanced water level control, OMAX waterjets unsure safe and clean working environment. Elevate your craftsmanship and achieve stunning, professional-grade stonework, tilework, and marble creations with OMAX waterjets. More Information

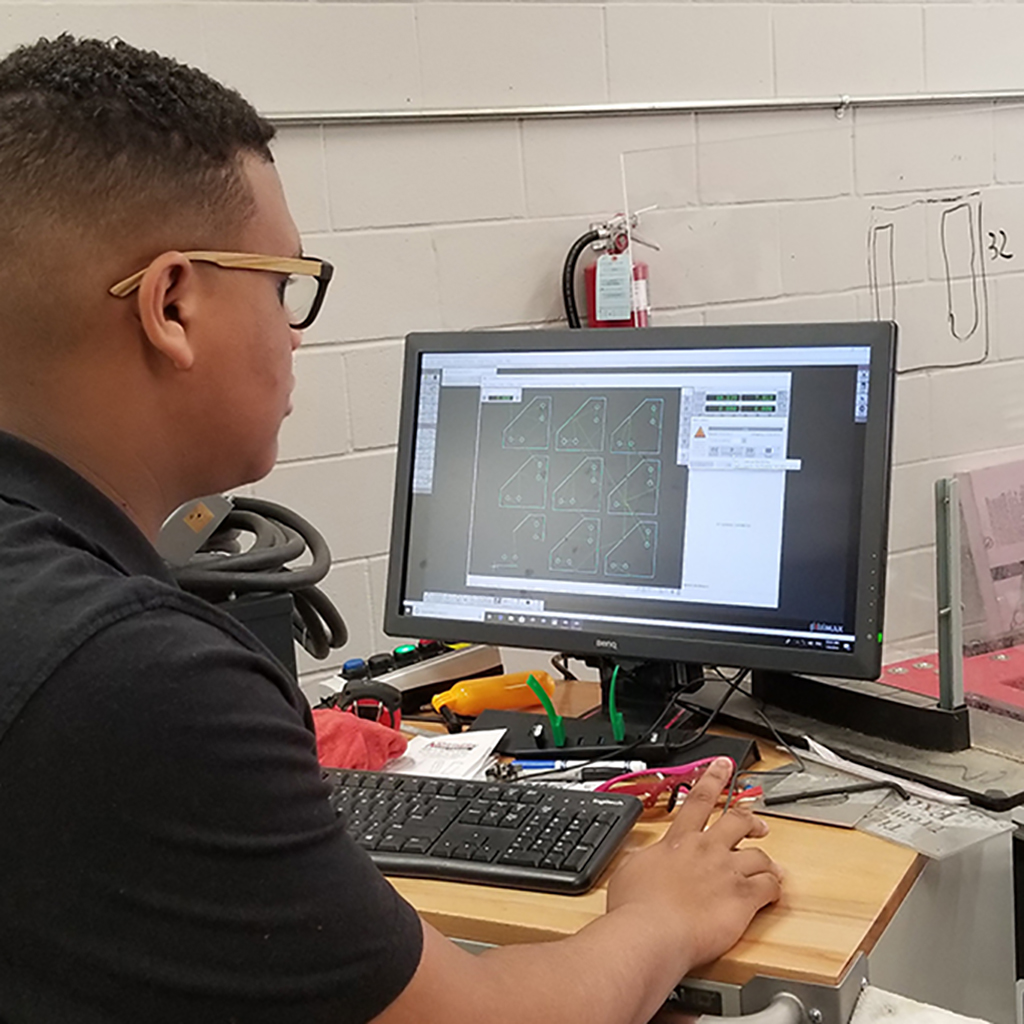

EDUCATION

Whether for training or research, our waterjets serve as learning tools for high school, trade school, college and university engineering and physics labs.

AEROSPACE

Abrasive waterjet has major advantages when Cutting carbon fiber. No need to change tooling. No special considerations or restrictions due to heat buildup. No melting. No hazardous fumes requiring costly air handling equipment. Any fiber-reinforced material, including Kevlar reinforced personnel armor, can be quickly and cleanly cut without the drawbacks that come with conventional machining.

FOOD PROCESSING EQUIPMENT

From the orange juice you drink at breakfast to the fish filet you had for dinner, abrasive waterjets were likely used to make the machines that process many of your favorite foods.

METAL SERVICE CENTER

The versatility of OMAX abrasive waterjets allow for cutting a wide variety of materials and thicknesses without any material distortion. Aluminum, steel, titanium: complete any order without tool changes. Modern waterjet systems are optimized to cut materials between ¼ inch up to 3 inches thick. Given enough time and consideration for taper, waterjets can cut as thick as you want. More Information

.jpg)