LEARN ABOUT WATERJETS

LEARN ABOUT WATERJETS

WHAT MATERIALS CAN A WATERJET CUT?

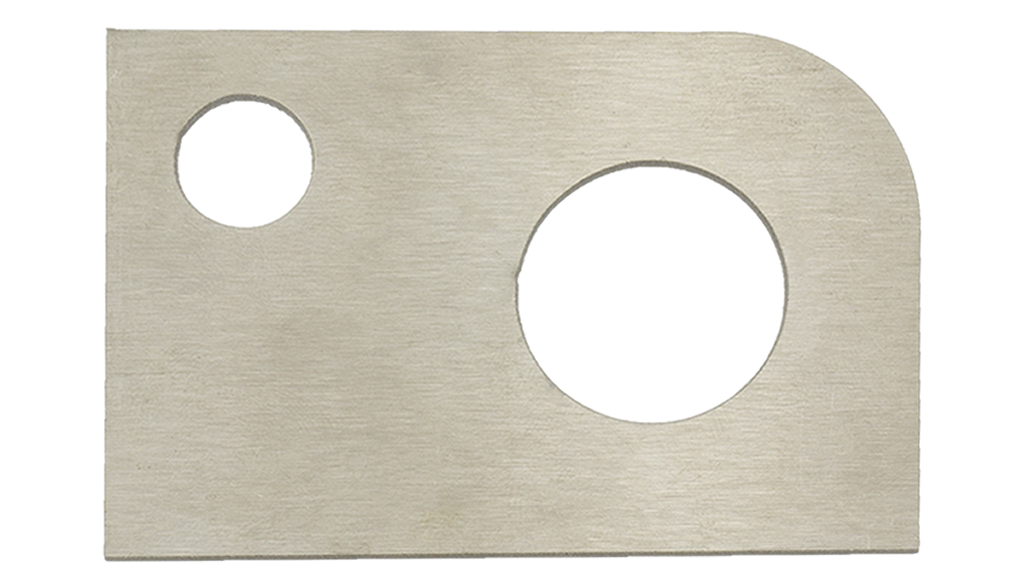

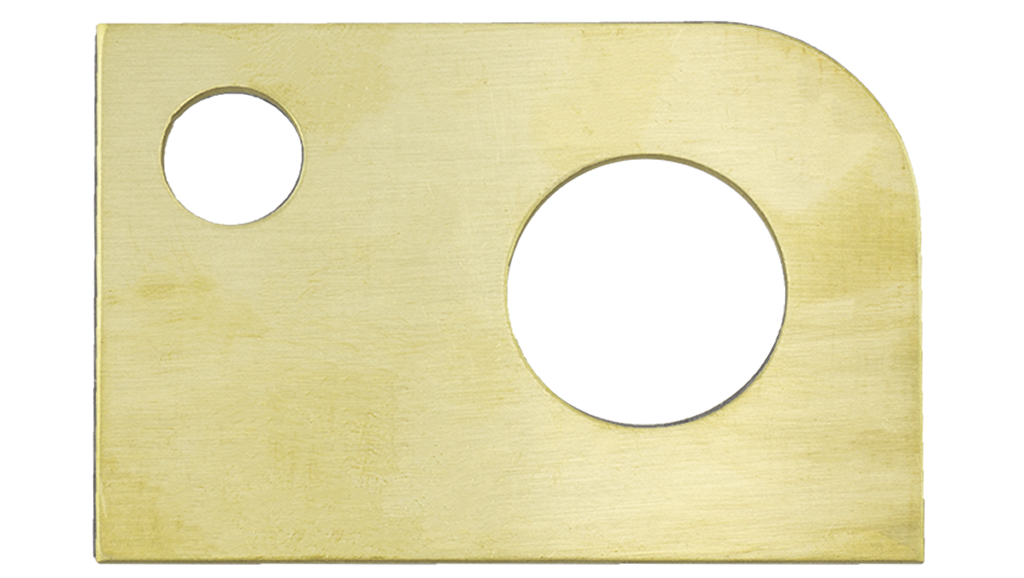

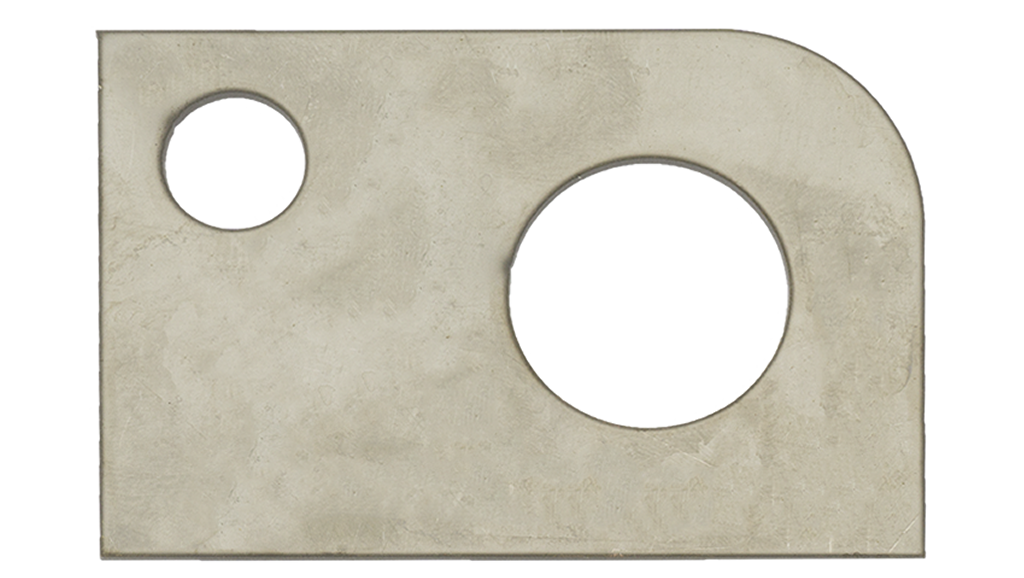

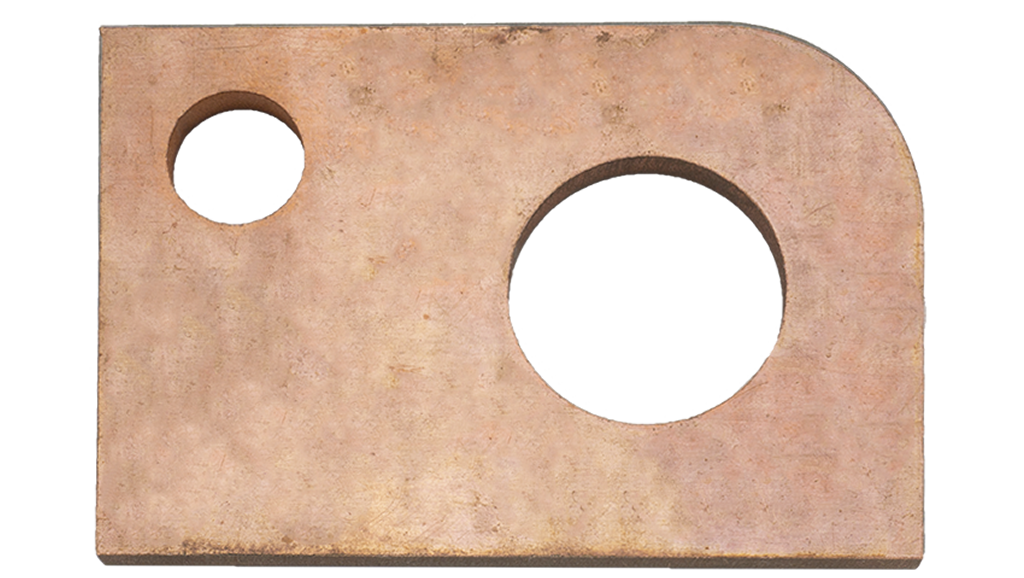

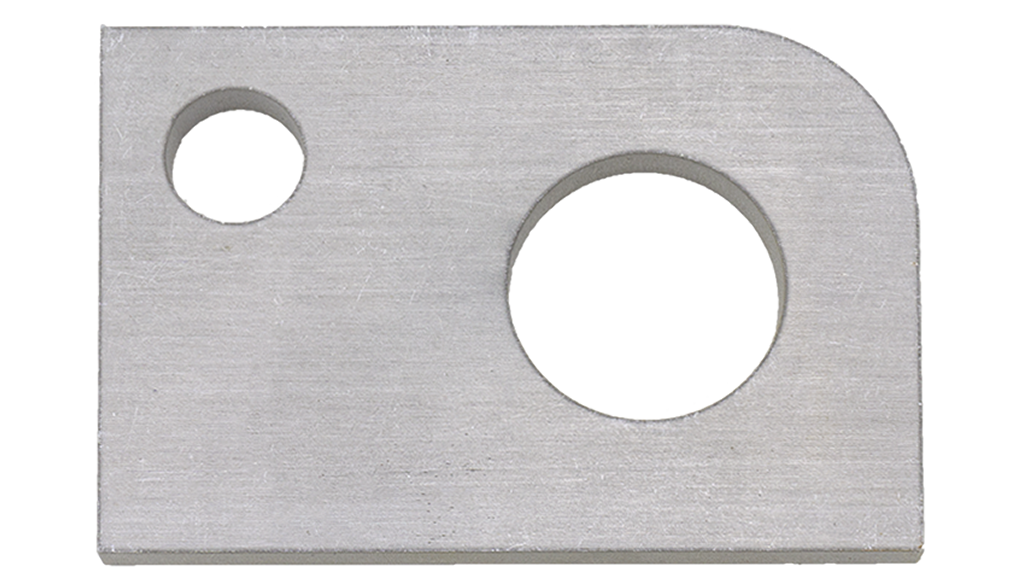

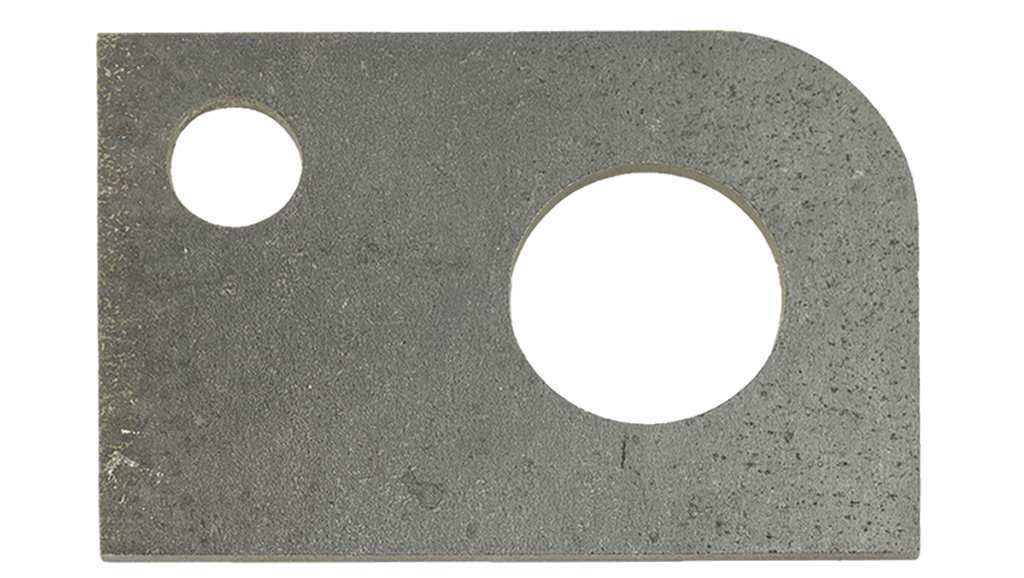

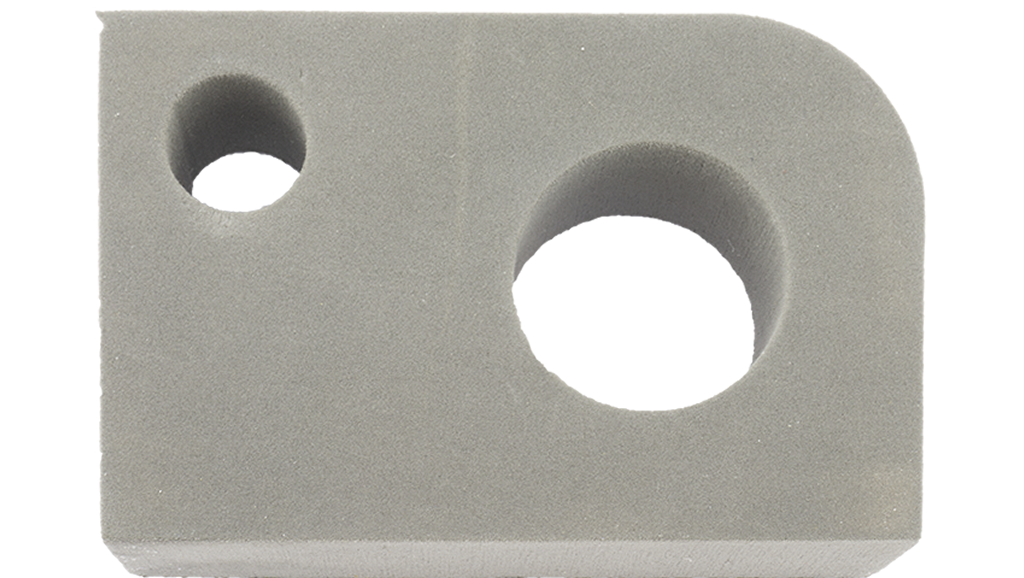

METALS

Waterjet machines cut all types of metals: hardened tool steel, aluminum, titanium, and a host of exotic metals that prove difficult to cut with other tools or processes. Cutting with a waterjet produces a smooth edge with no burn marks, cracking or excess burrs. In addition, since waterjet is a cold cutting method, there are no heat-affected zones.

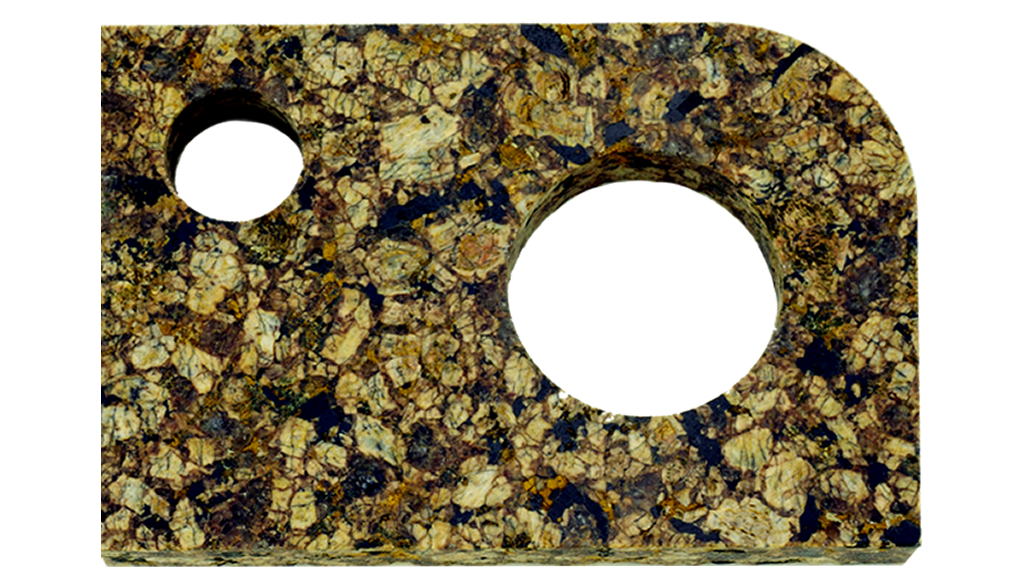

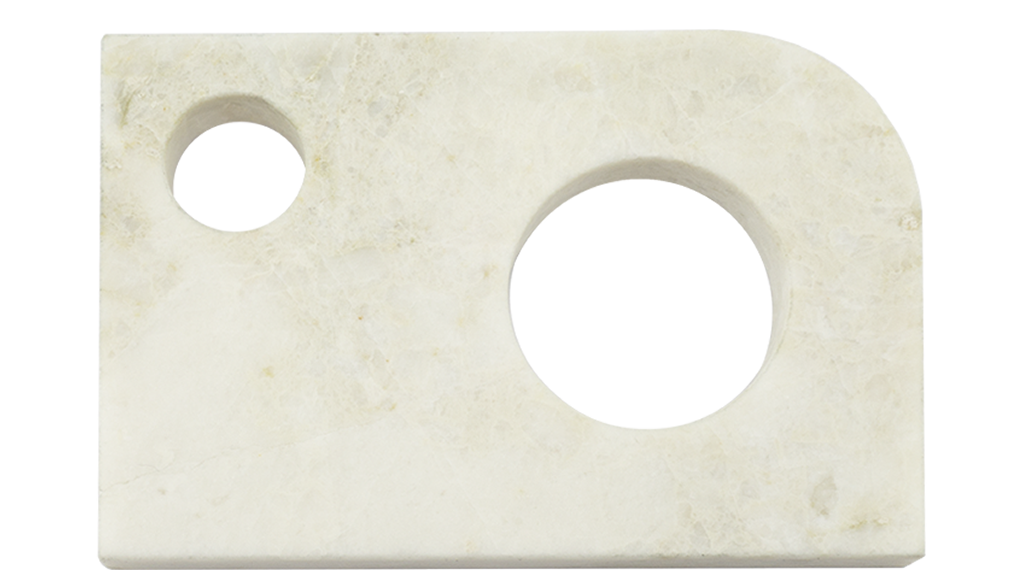

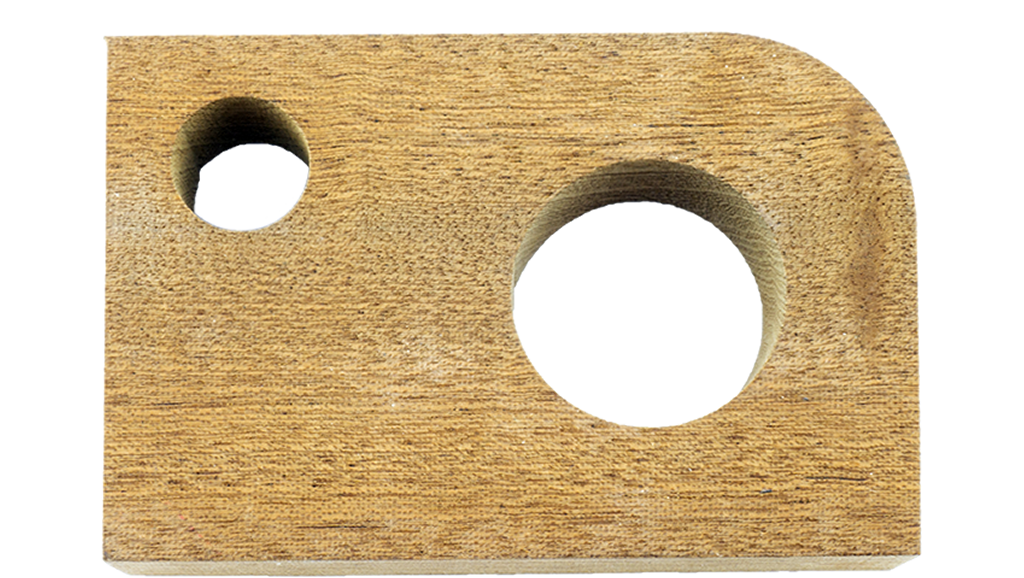

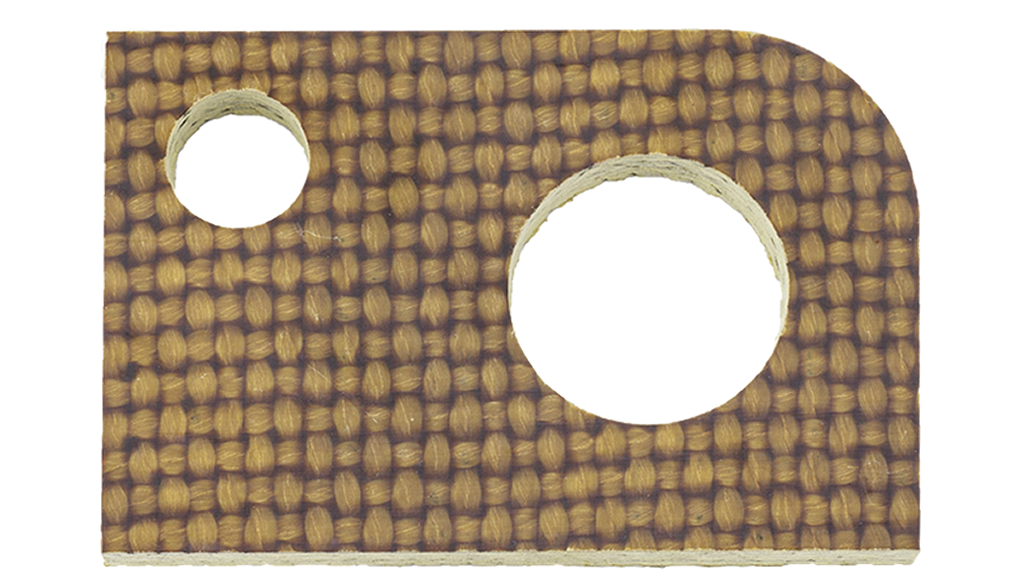

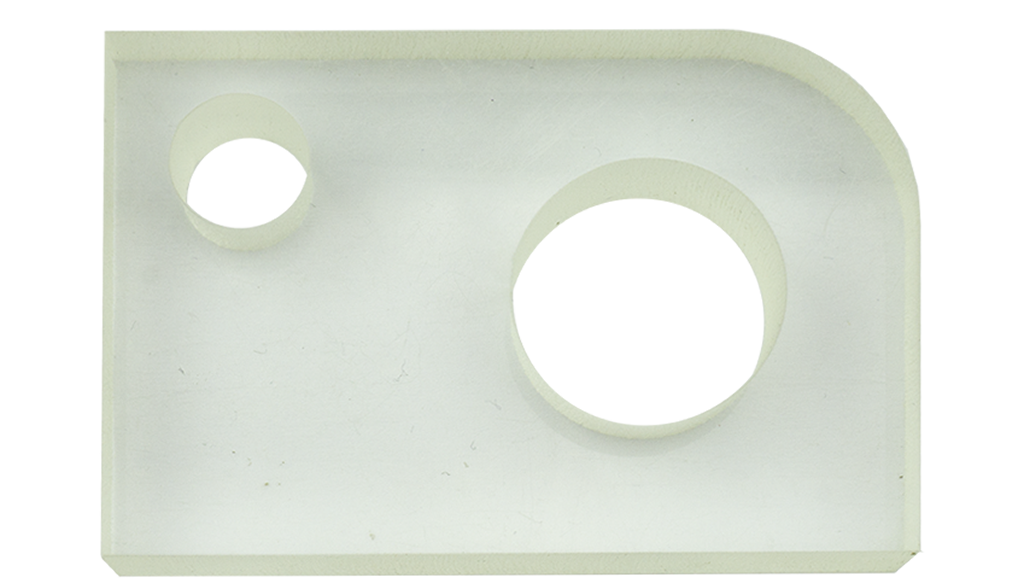

NATURALS

Glass, stone, or wood, waterjets have the capability to fabricate with nearly any material under the sun. With specialized techniques such as low-pressure pierce, water-only cutting, and vacuum assistance a whole host of natural materials can be machined perfectly.

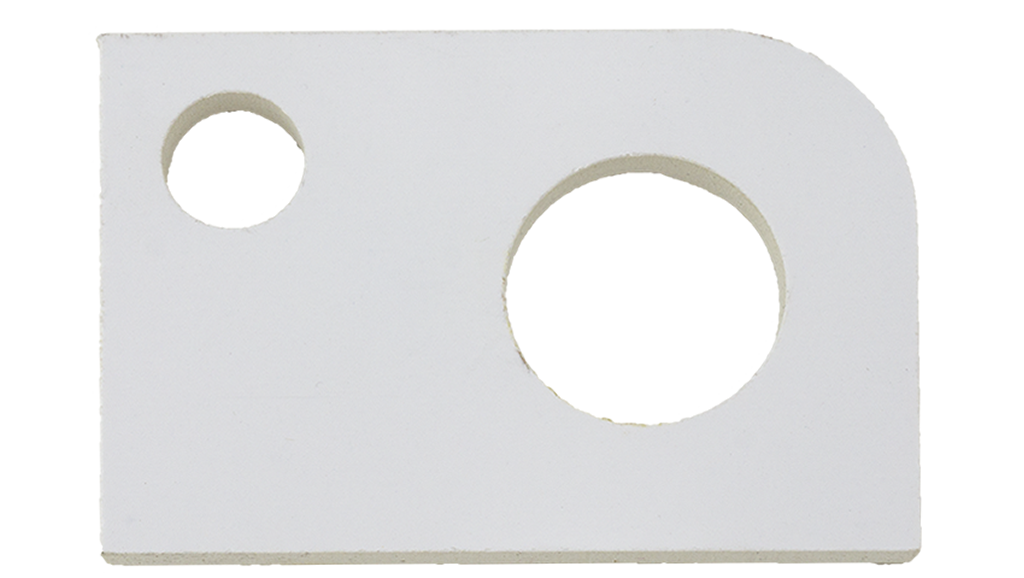

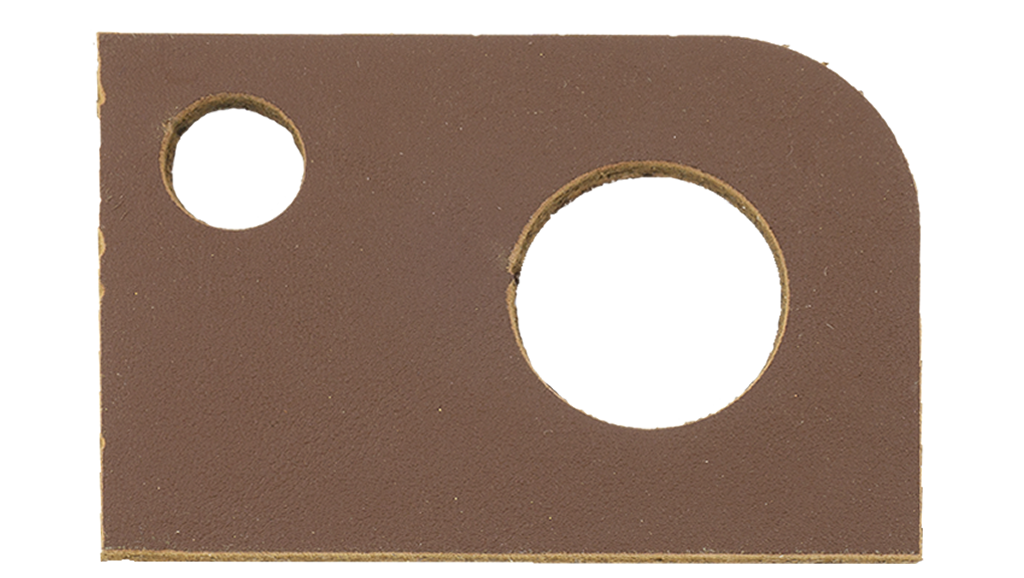

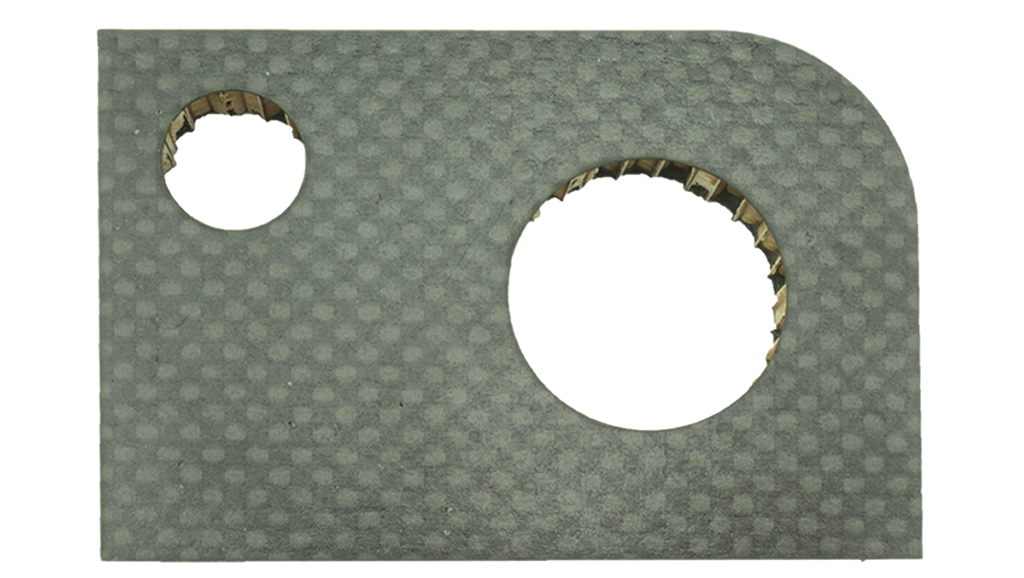

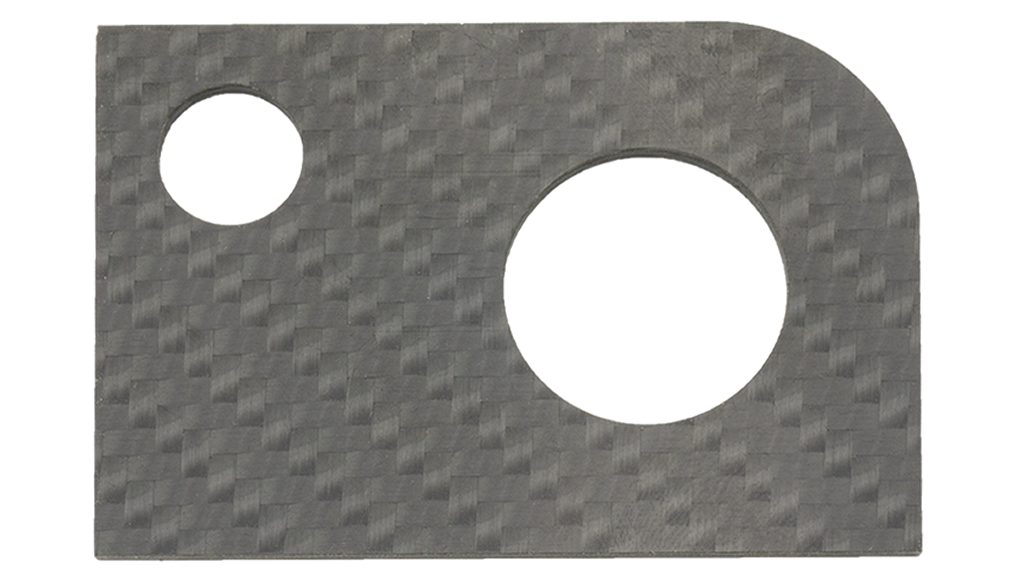

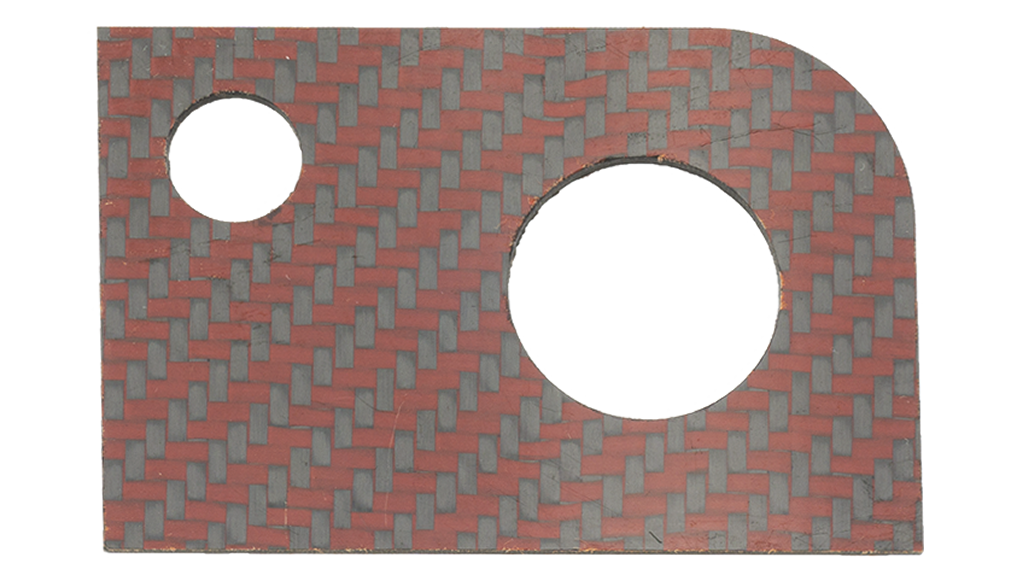

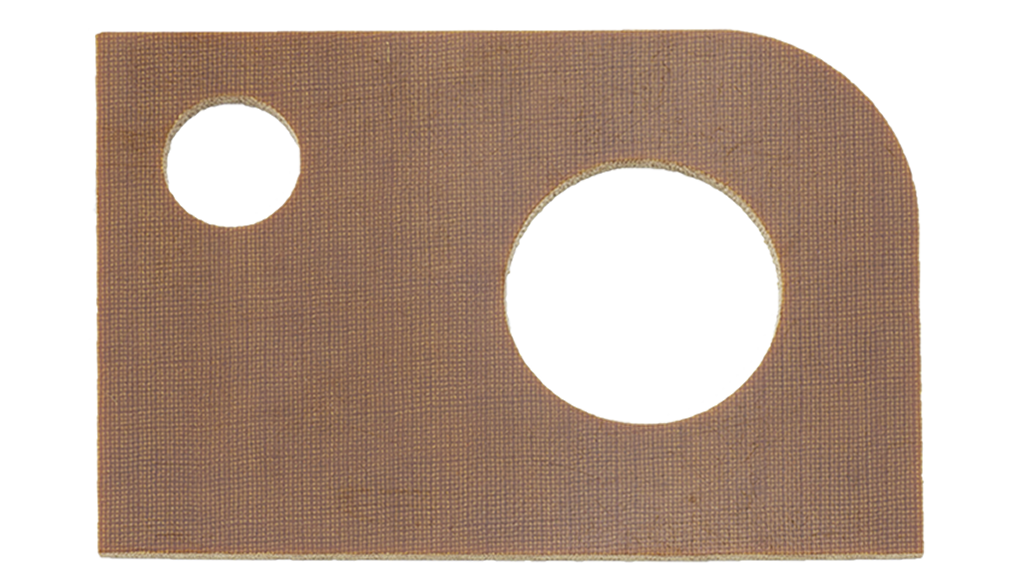

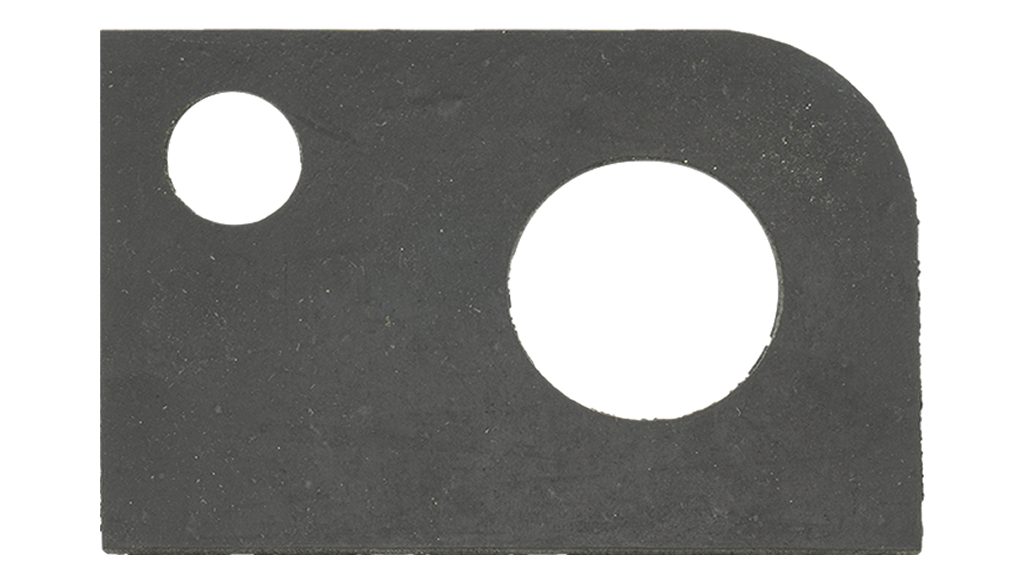

COMPOSITES

Abrasive waterjet has major advantages when Cutting carbon fiber. No need to change tooling. No special considerations or restrictions due to heat buildup. No melting. No hazardous fumes requiring costly air handling equipment. Any fiber-reinforced material, including Kevlar reinforced personnel armor, can be quickly and cleanly cut without the drawbacks that come with conventional machining.

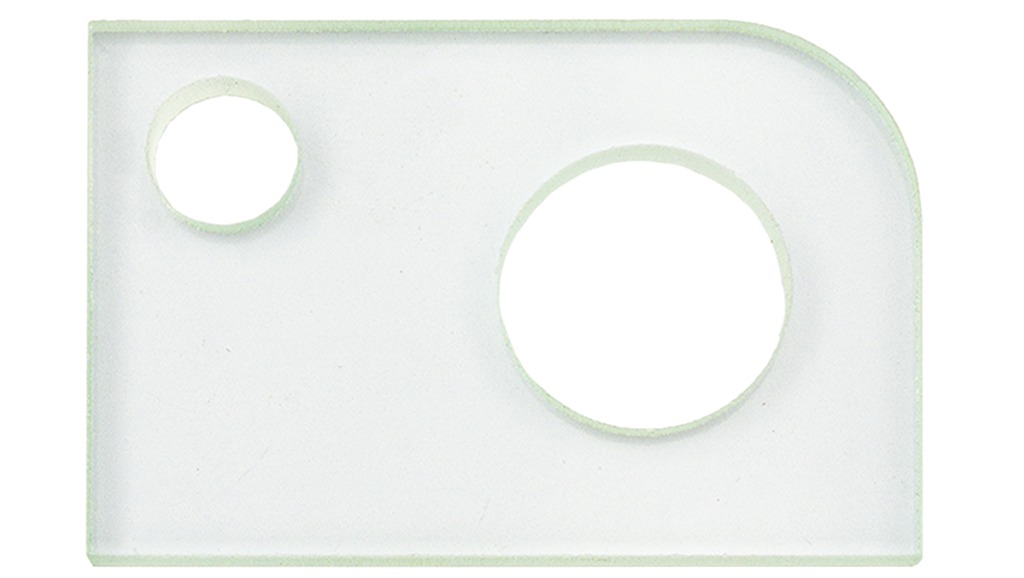

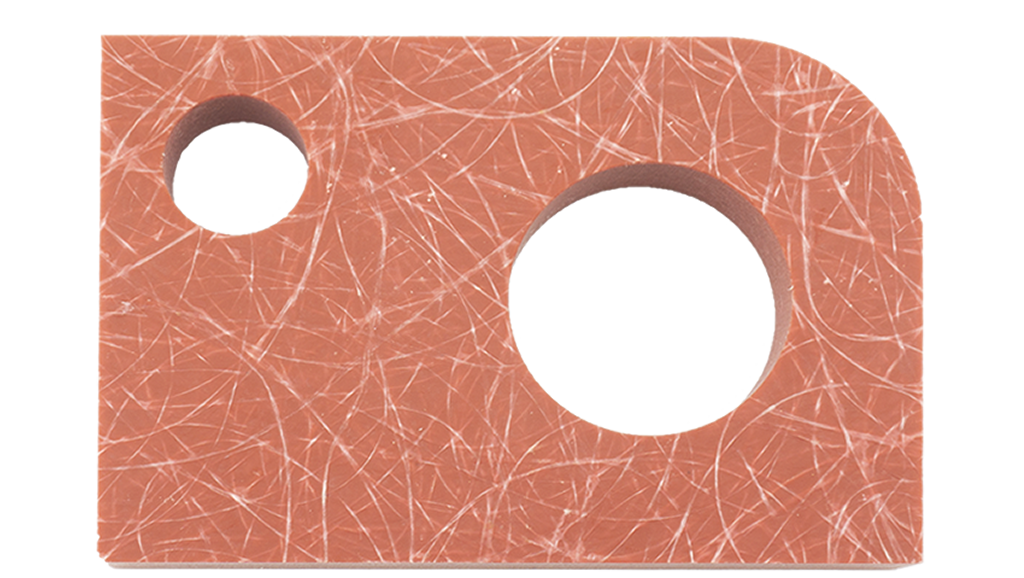

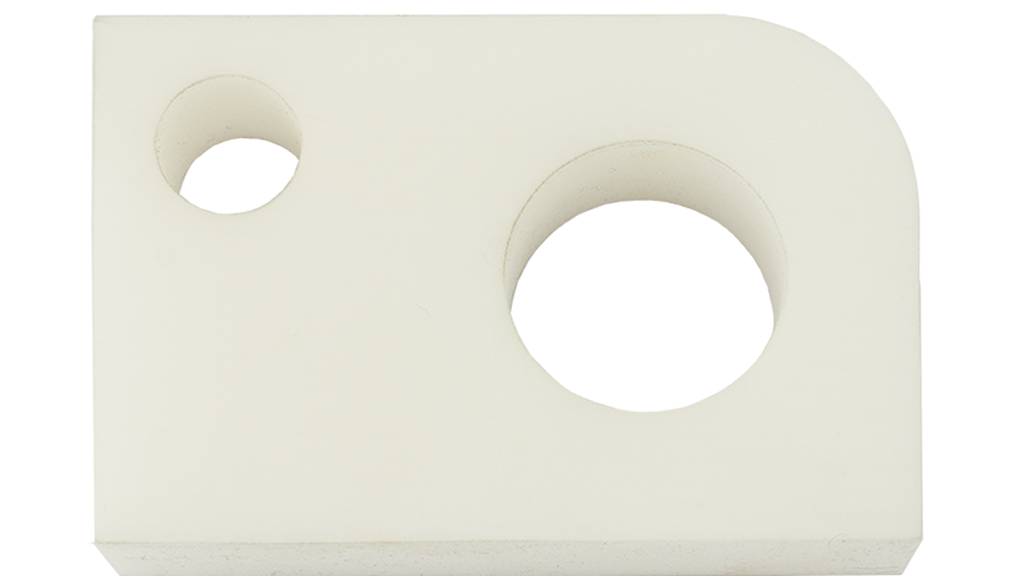

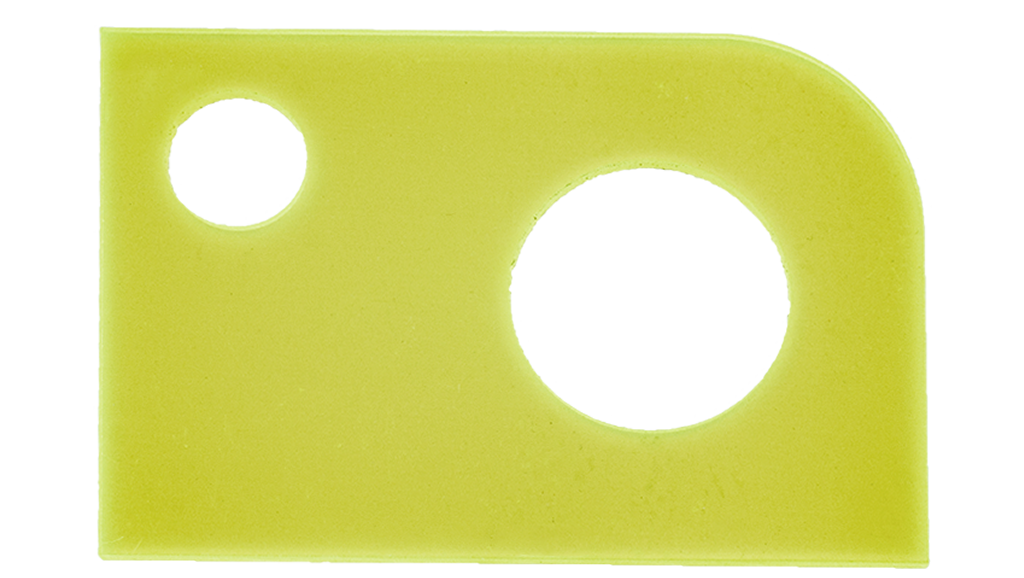

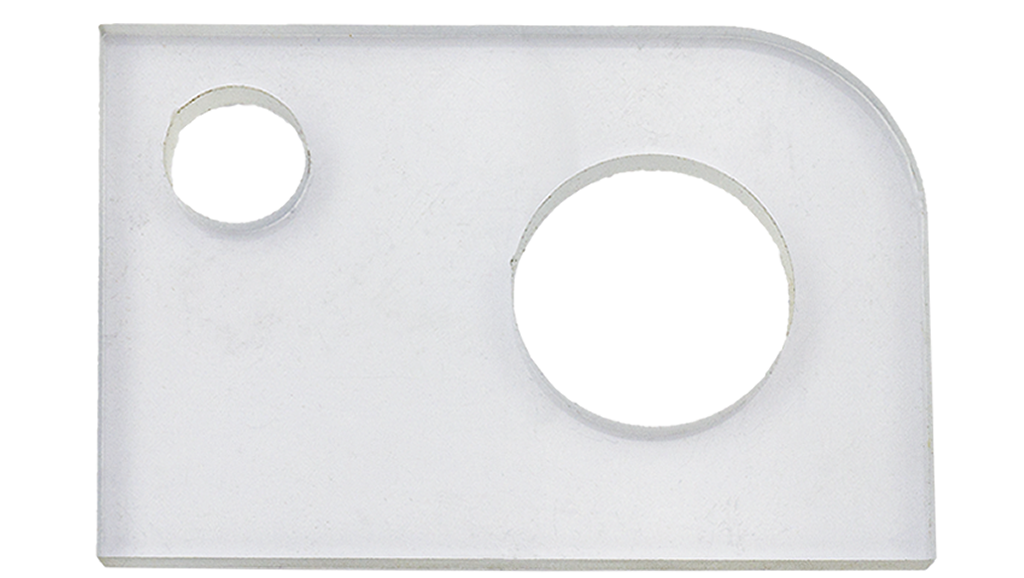

PLASTICS & RUBBER

The material distortions associated with machining plastic on conventional CNC machines no longer comes into play when using the cold cutting method of a waterjet. The ability to easily machine foam, rubber, and acrylic as well as all the previously listed materials gives waterjets an edge as a multi-use value-add tool. The versatility of a waterjet is what makes it so essential to any machine shop.