Service & Support

CONTACT TRAINING

Contact us at training@omax.com if you have questions about any of the training options OMAX offers.

TRAINING FACILITIES

Training classes held at OMAX headquarters, located in Kent, WA, are conducted in a state-of-the-art training facility, which includes a software training lab and a fully functional machine training lab. Classes are designed with a hands-on approach, and class size is limited to assure student participation in learning activities.

CLASS REGISTRATION

To sign up for training or for additional information on any of the training resources or classes, call Technical Training at:

OMAX Corporation (800) 838-0343 or (253) 872-2300 and ask for Training, or e-mail training@omax.com.

TRAINING PROGRAM DETAILS

Operator Startup Training

There are two options available for abbreviated Operator Startup Training.

Contact training@omax.com to learn how to access your online learning resources.

Option 1

OMAX provides self-paced eLearning modules that walk you through the steps of safely making a part, from loading the software, to fixturing and cutting the part.

Option 2

OMAX also provides recordings of instructor-led virtual training sessions to give your operators information to help get them up and running. These sessions follow the same topics and information we cover during in-person training at the factory. Contact training@omax.com to access your applicable product recordings.

Operator Training

Training courses are offered each month at the OMAX headquarters facility in Kent, Washington, located in close proximity to Seattle Tacoma airport. The Operator Training program is designed to lead you step-by-step through the process of making parts—from drawing to cutting. It gives you practical, hands-on experience in how to operate and maintain your equipment following best practices that have been tried and true in the lab and in the field. We provide you the information, practice, and resources to assist you in effectively operating and maintaining your equipment long after the training has ended.

Questions?

Contact training@omax.com

Additional Training

OMAX also offers other free training-on-demand opportunities through video instruction on software and maintenance, through its extensive IntelliMAX software help systems, and the OMAX Support Site.

Customized Training

OMAX offers fee-based on-site, at OMAX, and/or online training sessions customized to meet specific needs of both new and existing customers. The Training Manager works with you to determine the optimum training focus, based on your company goals.

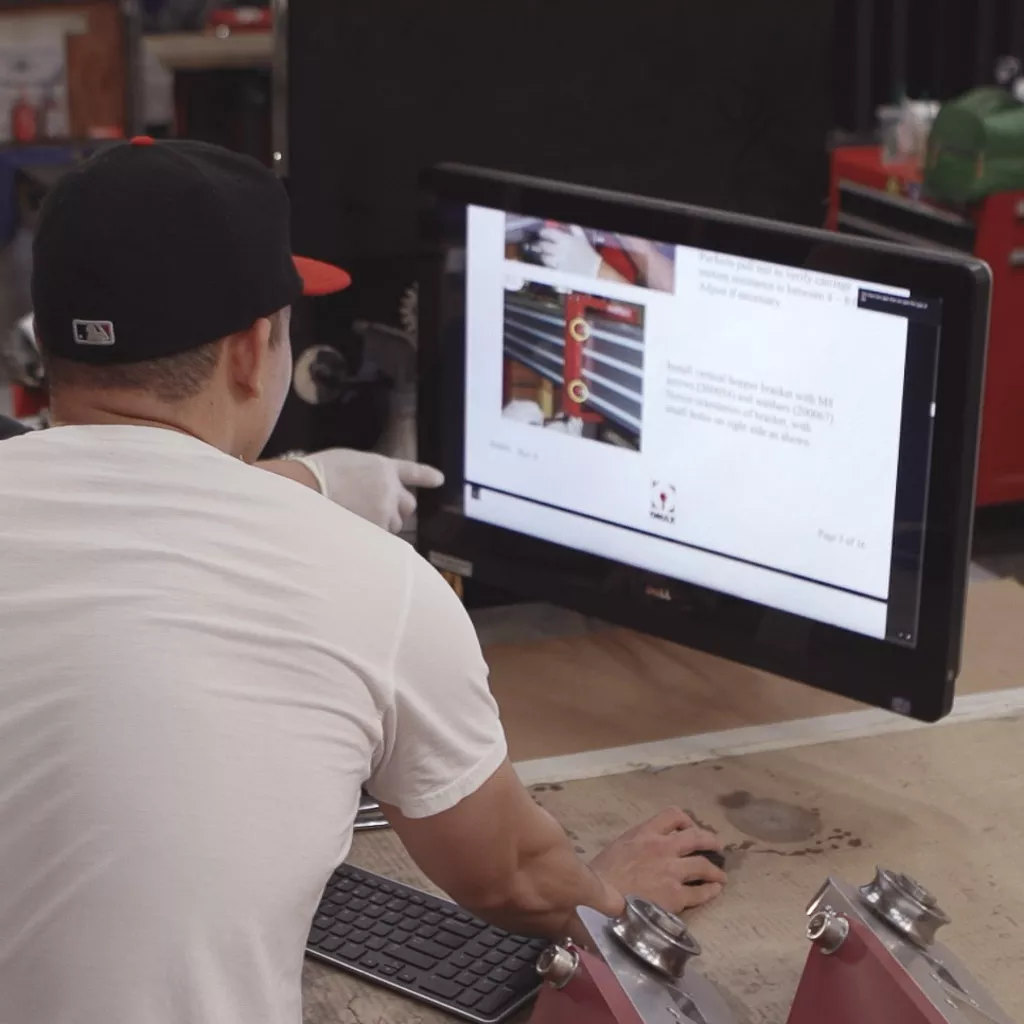

TRAINING MATERIALS

In addition to the hands-on training, OMAX training materials contain detailed step-by-step instructions for performing tasks related to operation and maintenance of OMAX abrasive waterjet systems. Designed to be used "on demand" when you need them, these instructional materials provide you information to be self-sufficient in operating and maintaining your equipment. Operators who have used these materials say they are some of the best written materials they've seen in the machine tool industry!