Tips & Tricks

Spend Less on Garnet with OMAX

As discussed on this website and in numerous trade magazines, OMAX abrasive waterjet systems can save you money on consumables (EnduroMAX 50 hp consumes as little as 1/3rd of the water used with an intensifier pump). But did you know that operating an OMAX abrasive waterjet system also allows you to cut using less garnet than competing brands?

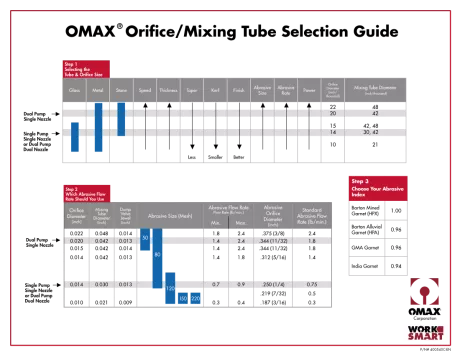

To understand exactly how garnet cost is reduced, we need to understand garnet flow rates. When running a waterjet, the operator sets the garnet flow rate based on the size of the machine’s nozzle orifice and mixing tube diameter. If there is too much garnet, the mixing tube won’t be able to handle the volume, leading to clogs. Too little garnet will prevent optimizing your separation speeds resulting in inefficient cutting.

See the image below for a quick reference:

Whatever the garnet flow rate is set to, it will be constant throughout your entire cut (unless you add in specific programing for your controller to change the flow rate mid cut). Often, the higher the flow rate the quicker the separation speed. This sounds counter-intuitive since we are discussing reducing garnet use, but the key is to have greater control over separation speeds, and this is exactly where OMAX is different than competing brands.

OMAX’s IntelliMAX software is developed alongside the abrasive waterjet hardware. Using empirical data on how the jetstream behaved with the specific configuration of nozzle, abrasive, the material cut, etc., OMAX developed software that adjusts to whatever process is occurring at every single point along a toolpath. OMAX’s software takes advantage of better computing processing power and utilizes better code capabilities with a stronger understanding of corners and motion control. This amounts to faster cutting resulting in cost savings on water, electricity, and garnet usage.

Consider a real-life example involving cutting a 40-inch tool path of a Geneva wheel. A 94ksi intensifier pump with second-rate software can cut the tool path in 50 seconds using one pound of abrasive. The same tool path, cut with a 60ksi direct-drive pump paired with better software, takes 41 seconds and only .68 lbs. of abrasive. The numbers speak for themselves. It’s easy to see how improved software complements the efficient direct-drive pump even if those numbers don’t seem like a huge difference when cutting a single part.

Let’s say you have a run of 400 of these Geneva wheels. When using the intensifier pump with sub-par software you are consuming 400 lbs. of abrasive. The direct-drive pump paired with OMAX’s IntelliMax software only used 272 lbs. With garnet costing approx. $0.55 per pound, your savings is around $70 just on garnet alone. Over time, that adds up. With the OMAX EnduroMAX 50HP pump consuming as little as a third of the water used with an intensifier pump, the savings are even greater.

The OMAX abrasive waterjet system allows you to perform all your cuts faster and using less garnet than competing brands to deliver more impressive cost savings as compared to other pumps. When combined with other built-in efficiencies on water and power, the math is simple: the faster you cut, the less garnet and water you use, the more money you save.