News Articles

Excerpt from Fabshop Magazine

Abrasive Cuts

Titanium weighs half of what steel does and is significantly harder than both steel and aluminum. That is why the aerospace and defense industries have been using titanium as a material in many of their components. In both commercial and military aerospace, they are always looking for lighter weight solutions. In addition, the medical industry often uses the titanium offers a resistance to corrosion making it the most biocompatible metal available. Unfortunately for manufactures for these industries, titanium tends to be a very slow and often costly process. However, there is a solution for faster, easier, and more cost-effective titanium cutting -- abrasive waterjet.

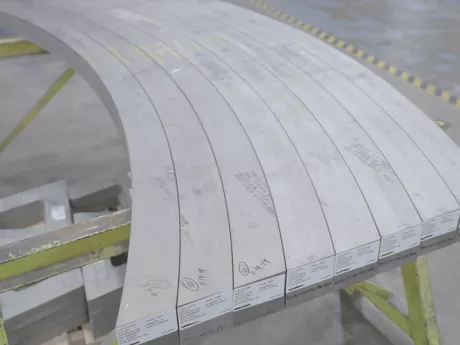

The one-inch thick part shown above is from OMAX’s IntelliMAX Make. The cut path of the part is 40 inches. If we were to cut this part in aluminum using an OMAX waterjet with a 50-horsepower pump, it would take approximately five minutes. That is a fast cut with complex geometry. But the one-inch aluminum may not be strong enough for the application. In steel, the same part with the same setup takes 15 minutes to cut. The steal part is stronger than the aluminum part, but also take up several more minutes of cutting time. This part in titanium only take 10 minutes and is stronger than either of the other two options.