Tips & Tricks

IntelliMAX Software Amplifies Waterjet Efficiency

Working with difficult-to-operate software that lags more than it simplifies just won’t cut it with today’s demanding lead times. In addition, shops need technology that enhances the well-established efficiencies of waterjet cutting like versatility, precision and minimal waste.

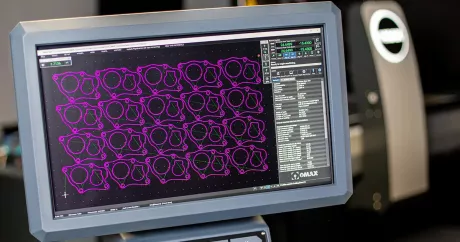

The IntelliMAX Software Suite amplifies the efficiency of waterjet cutting through multiple layers of programming.

Enhance versatility

- Explore numerous tool path fonts with IntelliMAX’s LAYOUT function to find the right match for any waterjet cutting project. You can also discover versatility through the various tooling options that can be used for your waterjet when designing an overall layout.

- With the MAKE function, find even more versatility through its ability to adjust waterjet cutting processes for varying material thicknesses.

- The IntelliCAM function of the suite is fast and easy to use and allows you to develop 2D part designs for using 3D models.

Optimize precision

- With LAYOUT, the program creates a tool path for you as you design. It provides a preview of your overall design and the functionality behind it so you can ensure your cut is as close as possible.

- Creating even greater precision and waterjet cutting speed, the MAKE function allows you to draw before cutting, and places your cutting tool at the exact starting point.

- IntelliCAM’s intuitive functions and helpful cutting plane previews are core to developing precise 2D prints from 3D models.

Reinforce minimal waste

- Because LAYOUT enables design before waterjet cutting, minimal waste is created by eliminating the risk of error and therefore creating less physical waste of materials.

- In addition to materials, job shops can avoid wasting precious time and money with the IntelliMAX software suite. The MAKE function saves time by pre-estimating both the amount of time and cost of each cutting process. INTELLICAM also allows for faster part design to waterjet cutting production with its ability to convert 3D models into 2D designs.

Abrasive waterjets are well known for their efficiency through versatility, precision and minimal waste. The IntelliMAX Software Suite amplifies an already efficient cutting process. Further, the supported file formats of the IntelliMAX suite features the broadest file support in abrasive waterjet software.