Media Center

MEDIA CENTER

Tips and Tricks

Abrasive Waterjet Machines: The Cutting Edge for Defense Manufacturing

Learn how abrasive waterjet cutting technology from OMAX provides efficient, flexible and profitable part processing for the defense industry. Read

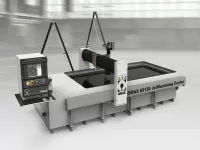

Revolutionize Your Workflow: Add Waterjet Cutting

Enhance your shop’s capabilities with waterjet cutting technology. Discover how abrasive waterjets offer unparalleled versatility, allowing you to cut through diverse materials, reduce outsourcing costs, and minimize waste. Boost your profitability and efficiency by integrating waterjets into your workflow, regardless of your shop size. Explore OMAX's range of waterjet machines and transform your business today. Read

OMAX Order: The One-Stop Shop for Ordering OMAX Parts and Services

OMAX Order is OMAX’s innovative digital solution that puts guaranteed service and support in the palm of your hand with your abrasive waterjet cutting. This mobile app creates convenience, maintains efficiency and provides peace of mind for both your business and everyone on the shop floor. Read

Press Releases

Hypertherm Associates and BLM GROUP form a strategic partnership

Hypertherm Associates and BLM GROUP announce a strategic partnership agreement aimed at expanding the market reach of their respective solutions. The two industry leaders will collaborate to offer premier solutions to customers through BLM GROUP’s laser cutting and tube bending systems and Hypertherm Associates’ plasma and waterjet cutting products and software. Read

Hypertherm Assoc. innovates at EuroBLECH 2024 with an immersive booth

At EuroBLECH 2024, Hypertherm Associates will bring together its cutting-edge technologies under one roof in Hall 13, Booth E158, where visitors can explore the full spectrum of industrial cutting solutions. Read

Hypertherm Assoc. selects Aaron Brandt as successor to CEO Evan Smith

Brandt will become the third CEO since Hypertherm Associates’ founding in 1968, following the strong leadership legacy of co-founder Dick Couch, CEO from 1968-2014, and Evan Smith, who succeeded Couch. Read

News Articles

Jetting to success

A New York-based shop implements waterjet technology and gains value Read

Digging deep

Fabricating projects in the engineering program’s shop helps prepare students for not only continuing their education after high school and, more importantly, for life. Kamal notes that students who are accepted into his program spend more than 1,000 hours studying engineering, including a lot of fabrication in class and as part of the after-school robotics club. Read

Waterjet Case Study: The complete package

Montreal packaging solutions manufacturer continuously invests in automation to keep pace with growth and keep its R&D on point Read

Videos

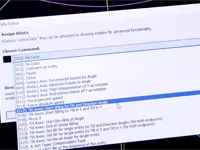

How easy is IntelliMAX XData

The OMAX IntelliMAX software has a powerful tool in its XData commands. Using XData is surprisingly easy to use, too, with only a few clicks needed to change settings on cutting paths. Read

The OMAX IntelliMAX Saw Function can save you time and inventory space

The OMAX IntelliMAX Saw Function lets you easily program a straight line cut to quickly trim material to shape or remove scrap skeletons. Read

Save material and money with these pre-cutting tips and tricks

The OMAX IntelliMAX software has lots of useful features that can benefit your bottom line. Here’s a couple useful tips in the IntelliMAX software that can help prevent expensive mistakes when cutting exotic materials. Read