Tips & Tricks

Cut Cool Parts With the Flexibility of Abrasive Waterjet Technology

Abrasive waterjets easily cut a wide variety of materials and cutting challenges, including thin or thick material, glass, carbon-fiber composites, titanium and special surface textures. But once you get accustomed to the power and versatility of these machines, it's easy to overlook their incredible creative potential.

Along with mainstream parts, our customers cut some exciting designs on our waterjets. Check out these cool results.

This carbon fiber part weaves the OMAX company name into an intricate continuous pattern of pentagons. The cell-like surface texture comes from the material itself. Cut on a MAXIEM abrasive waterjet, this geometric gem showcases our machines' consistent ability to cut variable composites without special challenges or considerations. In fact, MAXIEM machines cut just about everything, including really large parts, and do so at high volume.

This collection of objects showcases two special capabilities of OMAX abrasive waterjets. First, our software-controlled multi-axis A-Jet cutting head ramps up the versatility of any OMAX JetMachining Center. It cuts bevels, angled sides, countersinks and complicated 3D parts like this pipe and cuff. Its advanced features compensate for taper and produce finished parts without secondary processing.

Second, our purpose-built IntelliMAX software suite includes powerful features that can spark your creativity, like the artwork and patterns you see in the foreground here, produced through our IntelliETCH engraving capabilities.

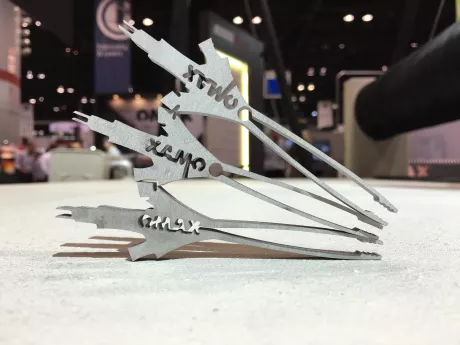

These tweezers, cut from a single piece of material, drawn on the advanced features of our multi-axis servo-controlled Tilt-A-Jet cutting head, which enables our OMAX JetMachining Centers to cut perfectly square edges with no special programming. It eliminates virtually all taper from the cutting jet by moving it to scrap areas of the material – and it changes angles in a heartbeat to reduce cutting time.

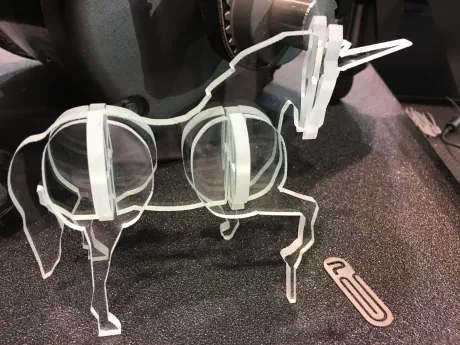

Abrasive waterjets excel at cutting glass, and this unicorn's 90° cut shows how routine our hardware makes the process of creating intricate art. Any OMAX, MAXIEM, GlobalMAX or ProtoMAX abrasive waterjet can produce this piece.

Jaws here owes its impressive teeth and fins to a MAXIEM waterjet equipped with our Motorized Z-Axis, which you can program through our 3D Path Editor software.

OMAX abrasive waterjets easily cut 3"-thick material – and go well beyond that given the time to cut through thicker substrates such as these, which we cut on an OMAX machine. When you work with material this beefy, plan on using augmented slats for proper support during the cut. You can cut your own special slats from a CAD file we supply.

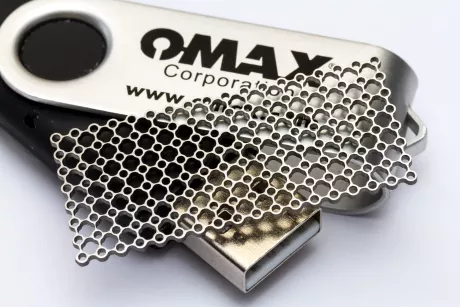

This tiny, intricate mesh owes its precise geometry to an OMAX MICROMAX JetMachining Center with Tilt-A-Jet cutting head, which provides the taper compensation necessary to cut it. With a 6'2" by 7'0" footprint and a linear positional accuracy of ±0.0001", this ultra-precision machine tackles everything from graphite to titanium, building prototypes or handling production duties.