Tips & Tricks

Save Money with OMAX Direct-Drive Pumps

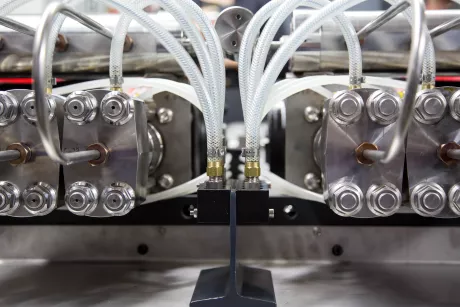

As far as machine tools go, OMAX abrasive waterjets are environmentally responsible. But not only that, by being environmentally responsible they can save you money. One aspect that makes OMAX waterjets so “green” is the OMAX lines of direct-drive pumps. These pumps don’t use hyrdaulic oil, so there is no need for costly chemical disposal when conducting maintenance. Also, the water and power consumption of a direct-drive pump is significantly less than other types of waterjet pumps. OMAX’s pump efficiency is a hallmark throughout the all the company’s pump lines: EnduroMAX, MAXIEM, GlobalMAX and even the small, but effective, ProtoMAX.

As an example, the EnduroMAX 50HP pump provides 60KSI of pressure allowing for fast accurate cutting. On average, the EnduroMAX 50HP uses 1.2 gallons of water a minutes. Intensifier pumps use as much as 4 gallons/minutes. Depending on your local government and how much they charge for water, the difference could be a substantial chunk of change. In 2016, a waterjet operating in California would save over $3000 using the OMAX direct-drive versus an intensifier pump. Today, a waterjet operating in the same location would still be saving over $2400.

Additionally, OMAX direct-drive pumps have an overall electrical efficiency of greater than 85%. This means that 85% of the electrical power put into the pump results in cutting power at the nozzle. The traditional hydraulic intensifier pump has an overall efficiency of 70% at best because of the energy losses associated with the hydraulic drive system. Not only do these losses result in waste heat that must be disposed of through an external cooling system, but they also mean that more expensive electrical energy must be used to achieve the same power at the nozzle. In comparison, a traditional hydraulic intensifier pump requires a 50 HP motor to achieve the same effective cutting power as a 40 HP OMAX direct-drive pump.

It is estimated that the average OMAX user who operates his system for 1000 cutting hours per year is saving approximately 9000 kWh of electricity per year compared to the use of an alternative abrasive waterjet system. At a national average of $0.10 per kWh, that amounts to $900 per year in savings on power alone.

Between water and electricity use of an OMAX direct-drive pump, you could be saving a total of $4000 a year over an intensifier pump. That may not sound like a huge amount, but it adds up. What about over ten years? Fifteen years? OMAX’s direct-drive pumps are the clear choice for financially savvy waterjet owners.