Tips & Tricks

Medical Shops Discover Waterjet Machining Versatility and Accuracy

Manufacturers of medical components are increasingly taking advantage of abrasive waterjet machining. It’s a versatile, accurate process that matches many medical partmakers’ needs while offering some capabilities that are unavailable from other machining processes. Read

The New OptiMAX is the Future of Abrasive Waterjet Cutting Technology

As the culmination of three decades of engineering expertise and experience, the OptiMAX debuted in early March to take waterjet cutting to the next level, which is exactly what the industry needs in an age of increasing production demands and a serious lack of skilled operators. Read

Maintain Water Quality and Temperature for Waterjet Machine Longevity

Two factors to consider for longevity and performance of your OMAX abrasive waterjet are clean water and proper water temperature. Both environmental elements directly impact the life of your machine’s internal components and, ultimately, its performance. Read

Top 5 "Secrets" to Get More Done with Abrasive Waterjets

If you're like many of our waterjet owners & operators, you'll be surprised at the productivity these machines can add to your shop's workflow and capabilities. That's because many manufacturers who've already integrated abrasive waterjet may not take full advantage of what the technology can offer, including these five best-kept secrets of production success. Read

How to Choose the OMAX Abrasive Waterjet That's Right for Your Shop

Abrasive waterjets offer a fast, flexible, and accurate method for cutting a wide range of materials. As the world’s largest single-source provider of waterjet cutting systems, OMAX designs and manufactures a comprehensive selection of waterjets from which users can choose to suit their specific production needs. Read

A Safe Waterjet Is a Productive Waterjet

Abrasive waterjets are safer than ever, but they still require proper safety precautions to be followed to ensure a safe and productive work environment. To keep operators and machines healthy and productive, OMAX offers safety guidelines related to each. While most shops may be familiar with these concepts, the guidelines must be applied consistently and reinforced routinely. Read

OMAX Helps Electric Vehicle Manufacturing Lighten Up

What other cutting technology can move from inches-thick steel and aluminum to plastic, foam rubber and carbon fiber – without changing a cutting head? Only waterjets can master all these materials and so many more. As a result, abrasive waterjets are essential technology for Electric Vehicles companies. Read

Accelerate Automotive Production With Abrasive Waterjets

Because abrasive waterjets can cut just about anything – including materials and thicknesses that other methods can't handle – our hardware enables shops to save time, eliminate outsourcing, reduce production costs, bring innovations to market and help students learn work-ready skills. Read

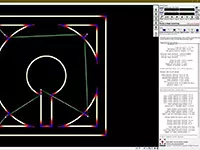

Maximize Productivity with OMAX Predictive and Preventive Monitoring

Production success depends on more than careful material selection, part programming and setup. OMAX IntelliMAX software makes every minute count, with real-time monitoring of equipment performance whether you're on or off the shop floor. Integrated software tools predict system behavior and video monitoring keeps on eye on actual performance. Read

Plan New Equipment Investments to Maximize Your Tax Deductions

When you're ready to add a new machine to your shop, an abrasive waterjet can expand your cutting capabilities and reduce your need to outsource processes. Along with the flexibility that an abrasive waterjet adds to your workflow, it also offers you a tax break. Read